Working Principle

Air-cooled chillers directly dissipate heat into the air through the air-cooled condenser. These chillers are ideal for areas with water shortages or where water supply is inconvenient.

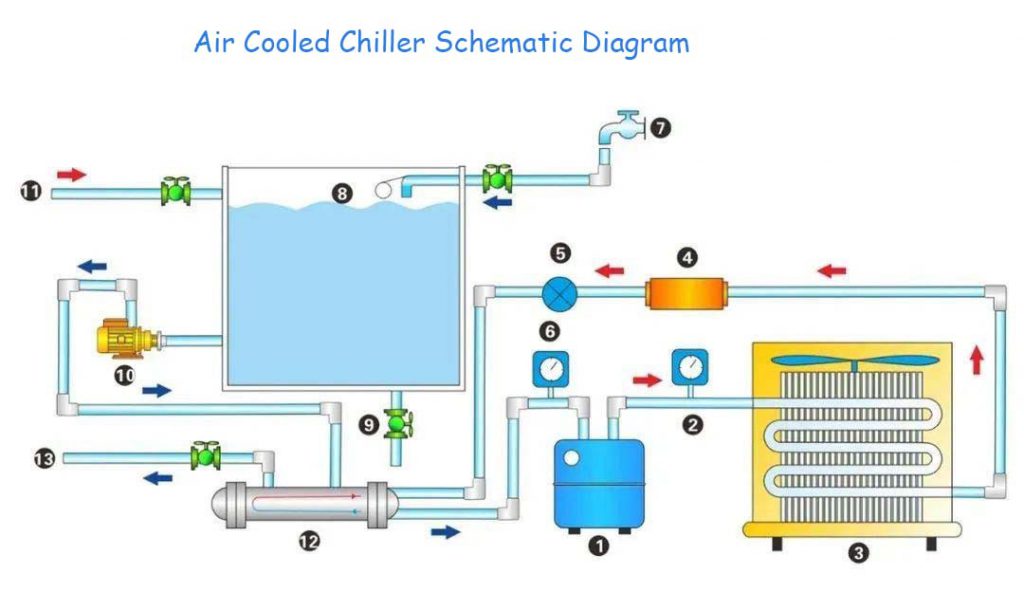

As shown in the air-cooled chiller operation diagram, the cooling process follows a closed-loop cycle:

- Evaporation: The refrigerant absorbs heat from the cooled object (e.g., chilled water) in the evaporator and vaporizes.

- Compression: The compressor extracts and compresses the refrigerant vapor into high-temperature, high-pressure gas.

- Condensation: The refrigerant gas enters the condenser, where it releases heat into the air and turns into a liquid.

- Expansion: The liquid refrigerant passes through the expansion valve, reducing pressure before entering the evaporator.

- Repeat cycle: The refrigerant re-vaporizes, absorbs heat, and the cycle continues.

Key Features of Air-Cooled Chillers

- Uses finned condensers with fans for heat dissipation, eliminating the need for cooling towers, cooling water pumps, or cooling pipelines.

- Easier installation compared to water-cooled chillers, especially for small-capacity units that require mobility.

- Higher condensation temperature than water-cooled chillers, leading to slightly higher power consumption.

- Avoids issues like scale buildup or water pipe blockages in regions with poor water quality, while saving water.

- Finned condensers require regular cleaning to maintain heat exchange efficiency.

Applications

Air-cooled chillers are widely used in:

🏥 Pharmaceuticals & laboratories

🧪 Chemical processing

🍔 Food & beverage production

🛢 Oils & coatings

🛠 Electroplating & machinery processing

🏢 HVAC & commercial buildings

🖨 Plastics, fiber, and laser cooling

Comparison: Air-Cooled vs. Water-Cooled Chillers

| Feature | Air-Cooled Chiller | Water-Cooled Chiller |

|---|---|---|

| Size | Smaller, compact | Larger due to cooling towers |

| Efficiency | Lower (higher power consumption) | Higher efficiency |

| Water Usage | No water required | Requires a steady water supply |

| Maintenance | Simple, easy to maintain | Requires cleaning & water treatment |

| Installation Cost | Higher upfront cost but no cooling tower | Lower unit cost but needs extra infrastructure |

| Best Use Cases | Areas with water shortages or space constraints | Large facilities with stable water supply |

Installation Considerations

1. Distance to Temperature-Controlled Equipment

- Shorter distances reduce pressure drop and cooling loss in pipelines.

- Makes operation easier if there is no remote control function.

2. Noise Impact

- Major noise sources: compressor, circulation pump, and fans (fans are the loudest).

- Small chillers (~65 dB(A)) can be installed indoors.

- Large units (above 20HP) should be placed outdoors or away from workspaces.

3. Water Supply & Drainage

- Automatic refill sources should be available for maintenance.

- If using manual refilling, only drainage needs to be considered.

4. Installation Environment

- Outdoor installation is preferred for better heat dissipation.

- Outdoor chillers have weatherproof designs but are more expensive.

- Remote control access for monitoring and troubleshooting is recommended.

Working Principle and Features of Air-Cooled Chillers